BHP has been supporting refinery operations for nearly three decades, for a half-dozen major energy companies

BHP supports our clients with activities involving

- Process simulations/modeling

- Project scoping

- Front-end loading

- Heat and energy balances

- MFDs, P&IDs

- Equipment Specifications

- Controls and instrumentation

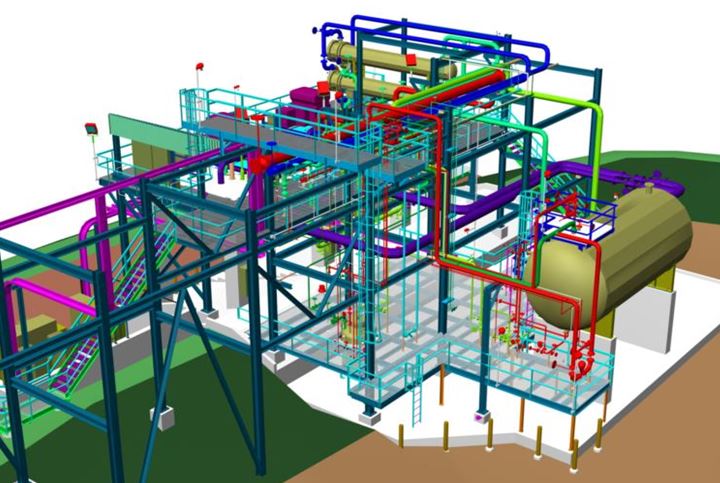

- Plot plans, equipment arrangements

- Feasilbility/Cost assessments

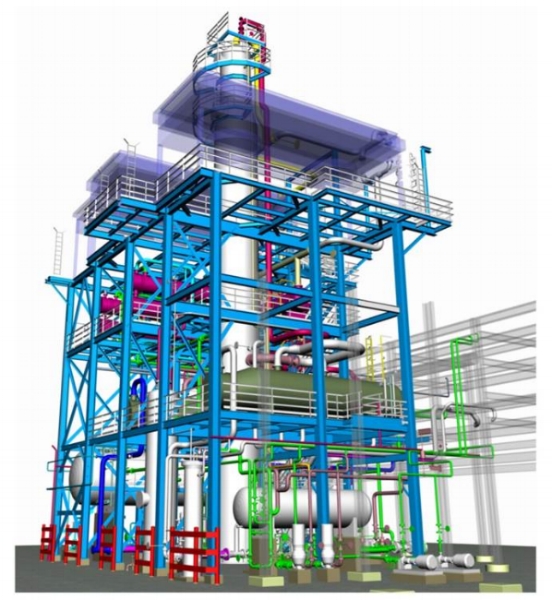

- Detail Design

- Civil/Structural

- Instrument/Electrical

- Mechanical/Piping

- Fabrication and Erection

- Pipling

- Civil/Structural

- Instrument/Electrical

- Inspection/QC

- Turnaround planning and management

Refining systems for which BHP has had direct project experience includes:

Alkylation Units

Asphalt

Benzene Extraction

Catalytic Reforming

Claus Sulfur Unit

Cogen Boilers

Cokers

Crude Unit

DCS Systems

Desalter

FCC Units

Flare Systems and PSVs

Hydrocracking

Hydrogen Plant

Hydrotreater

Isomerization

Naphtha Units

Olefins

Residual Fuel

Utilities

Vacuum Units

Waste Water Treatment

Wet Gas Scrubber

Recent Refinery Projects

Koch

- Boiler Feedwater RO unit

- Centralized control room

Valero

- Belco scrubber and ancillary equipment for HOC unit

- FCC unit modifications and upgrades- Three Rivers

- Heater energy recovery improvements- Three Rivers

- Amines unit

Flint Hills

- Low NOx burners for heaters

Trigeant Refining

- Asphalt modernization

- Asphalt blending

- Railcar Loading

Citgo

- East plant flare gas recovery

- West plant flare gas recovery

- #1 Crude unit revamp